Cantilever Bridge

A cantilever bridge is a bridge built using cantilevers, structures that project horizontally into space, supported on only one end. For small footbridges, the cantilevers may be simple beams; however, large cantilever bridges designed to handle road or rail traffic use trusses built from structural steel, or box girders built from prestressed concrete. The steel truss cantilever bridge was a major engineering breakthrough when first put into practice, as it can span distances of over 1,500 feet (460 m), and can be more easily constructed at difficult crossings by virtue of using little or no falsework.

A cantilever bridge is constructed using cantilevers, which are horizontal structures supported only on one end. With the right materials and engineering, a steel truss cantilever bridge can span well over 1,500 feet (460 m). This type of bridge has been used for pedestrians, trains, and motor vehicles. Cantilevers are especially useful for spanning a waterway without dividing it with river piers.

Engineer Heinrich Gerber built the first cantilever bridge in 1867. He had invented the hinge girder just one year before. With this new invention, Gerber was able to lengthen the cantilevers and build a bridge that was long enough to cross Germany’s Main River.

As of 2010, the Quebec Bridge in Canada holds the record for the longest single cantilever span. The simple cantilever bridge is 1,800 feet (549 m) long. In Scotland, the Forth Bridge is another famous cantilever bridge. Made of steel, the Forth Bridge uses balanced cantilevers on river piers and on land to make a combined span of 3,300 feet (1,006 m).

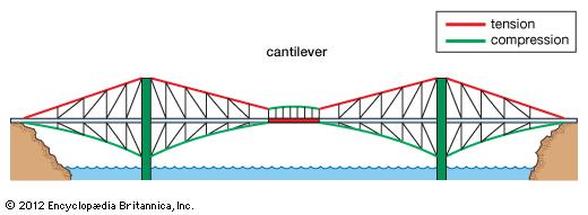

Cantilevers must be firmly anchored on one side in order to hold up the necessary weight on the free standing side and avoid shear stress. A common example of a small cantilever is a diving board. One side is firmly attached to the ground so that the other side can hold a person’s weight suspended over the water. Cantilevers must resist tension in the upper supports and compression in the lower.

Sometimes, a gap or waterway is too wide to be spanned by one cantilever on each side. In this case, a beam bridge or truss bridge is often placed between the arms of the two cantilevers, connecting them into one bridge. This type of bridge is known as a suspended span bridge.

A balanced cantilever is another technique for spanning long distances. In this situation, engineers construct a pier in the middle of the river. They then anchor two cantilevers on the pier, each facing the opposite direction from the other. These cantilevers, or anchor arms, meet with other cantilevers anchored in the ground or another pier to create one whole bridge.

The first step in building a cantilever bridge is to build and connect the arms to the shore. River piers for balanced cantilevers should not be built until the cantilevers that touch the land are completed. If a beam bridge or truss bridge is necessary, it cannot be added until the cantilevers are ready. The beam bridge is often built off-site and lowered with a crane into position.

Engineer Heinrich Gerber built the first cantilever bridge in 1867. He had invented the hinge girder just one year before. With this new invention, Gerber was able to lengthen the cantilevers and build a bridge that was long enough to cross Germany’s Main River.

As of 2010, the Quebec Bridge in Canada holds the record for the longest single cantilever span. The simple cantilever bridge is 1,800 feet (549 m) long. In Scotland, the Forth Bridge is another famous cantilever bridge. Made of steel, the Forth Bridge uses balanced cantilevers on river piers and on land to make a combined span of 3,300 feet (1,006 m).

Cantilevers must be firmly anchored on one side in order to hold up the necessary weight on the free standing side and avoid shear stress. A common example of a small cantilever is a diving board. One side is firmly attached to the ground so that the other side can hold a person’s weight suspended over the water. Cantilevers must resist tension in the upper supports and compression in the lower.

Sometimes, a gap or waterway is too wide to be spanned by one cantilever on each side. In this case, a beam bridge or truss bridge is often placed between the arms of the two cantilevers, connecting them into one bridge. This type of bridge is known as a suspended span bridge.

A balanced cantilever is another technique for spanning long distances. In this situation, engineers construct a pier in the middle of the river. They then anchor two cantilevers on the pier, each facing the opposite direction from the other. These cantilevers, or anchor arms, meet with other cantilevers anchored in the ground or another pier to create one whole bridge.

The first step in building a cantilever bridge is to build and connect the arms to the shore. River piers for balanced cantilevers should not be built until the cantilevers that touch the land are completed. If a beam bridge or truss bridge is necessary, it cannot be added until the cantilevers are ready. The beam bridge is often built off-site and lowered with a crane into position.